Mitsubishi Electric Hydrobox S Reversible Ersd-Vm2d Air Water Heat Pump With Ecodan E Suz-Swm40va 5.6 Kw R-32 Outdoor Unit

Mitsubishi Electric Hydrobox S Reversible Ersd-Vm2d Air Water Heat Pump With Ecodan E Suz-Swm40va 5.6 Kw R-32 Outdoor Unit is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

How shipping works

How shipping works

Shipping costs vary depending on the weight and shipping method of your order. Our shipping services:

- Standard Shipping: Estimated delivery within 2 to 5 business days

- Premium Shipping: Guaranteed delivery within 24 business hours

- Premium Shipping + Home Delivery: Guaranteed delivery within 24 business hours

See the tables for standard shipping prices for Italy and the Minor Islands and Disadvantaged Areas.

For more details on Premium Shipping, please visit the Premium Shipping page.

Customer service

Customer service

Our customer service team is dedicated to providing support to our customers with any issues or questions they may have before or after purchasing our products.

Use the direct communication channel to speak with one of our representatives, or send us an email at one of the addresses listed on the contact us page.

Our customer service team is made up of highly qualified professionals who are always ready to help customers resolve any issue or answer any question quickly and efficiently. We are committed to ensuring maximum customer satisfaction and providing the highest quality after-sales service. So, if you need assistance, don't hesitate to contact us; we'll be happy to help in any way we can.

Description

Description

NB: IF THE ITEM IS NOT IMMEDIATELY AVAILABLE, IT WILL BE POSSIBLE TO ORDER IT WITHIN 10 WORKING DAYS.

First ignition excluded

Mitsubishi Electric Hydrobox S Reversible Air-Water Heat Pump ERSD-VM2D 5 kW with ECODAN E SUZ-SWM40VA external unit

Hydronic module

- ERSD-VM2D

- SMALL SIZE

- Power supply Voltage/Freq./Phases V/Hz/n° 230/50/1

- Reversible Version

- Dimensions HxWxD mm 800 x 530 x 360

- Water content of the module system liters 5.2

- Water flow min/max l/min 5.00/36.90

- Voltage/Freq./Phases V/Hz/n° 230/50/1

- Expansion vessel system 10 litres

- Safety valve Mpa 0.3

- SUZ-SWM40VA

- Voltage/Freq./Phases V/Hz/N° 230/50/1

- Dimensions HxWxD mm 880x840x330

- Liquid diameter mm(in) 6.35 (1/4)

- Gas diameters mm(in) 12.7 (1/2)

- Max length (min) m 30 (5)

- Max difference in altitude 30 m

- Heating min/max -20°C/ + 24°C

- ACS min/max -20°C/ + 35°C

- Cooling min/max 10°C/ + 46°C

- R-32 refrigerant gas

- Air 7° / Water 35° Delta 5°C Nominal / Max Capacity kW 4,00/7,10

- Max water temperature °C 60

- Low Water Temperature 35°C (Mid Season)1 SCOP Rank A+++

- Average Water Temperature 55°C (average season) SCOP 3.29 Rank A++

- Air 35° / Water 18° Delta 5°C 5.60/7.00

- Power consumption Nom. / Max kW 1,12/1,53

Ecodan System

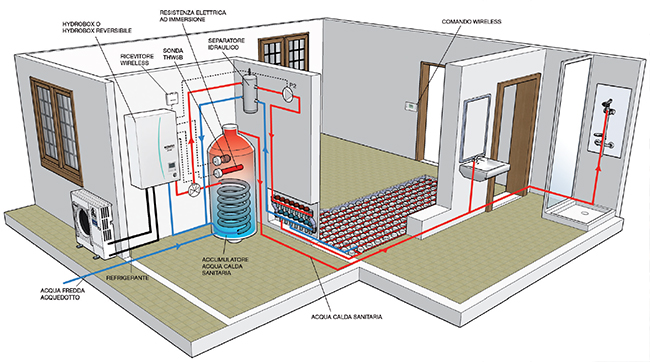

The Ecodan - split system is composed of a traditional external direct expansion unit (Power Inverter or Zubadan type) and a hydronic module to be installed inside, capable of producing cold and hot water for heating or sanitary use. The module is equipped with an FTC4 control unit

Hydrobox split

The Hydrobox is the indoor hydronic module for wall-mounted installation , in a very small space all the main components of the hydraulic system are enclosed.

A wide range of indoor units

The internal hydronic modules of the Ecodan® - Split line offer a wide range of choices:

- “Hydrobox” guarantees great flexibility of use and versatility of installation. It can be associated with a boiler for domestic hot water; there are various models including reversible ones with which it is also possible to produce chilled water for summer air conditioning.

- "Hydrotank" the simplicity and practicality of the "all-in-one", incorporating a 170, 200, 300 litre boiler for the production of domestic hot water. To the "Split" systems it is possible to connect an external unit of the "Zubadan" series to favour low temperature performance or of the "Ecodan®" series characterised by the widest range extension.

The Hydrobox is the indoor hydronic module for wall-mounted installation by Ecodan®.

All the main components of the hydraulic system are enclosed inside (heat exchanger, hydraulic circulator, expansion vessel, integrative electrical resistance and safety components).

Hydrobox has been designed with the utmost care to:

- Design, simple and elegant;

- Compact size, for indoor installations;

- Components located on the front to facilitate maintenance;

Hydrobox is developed in two versions:

- For heating and domestic hot water;

- Reversible, which in addition to the functions of the classic Hydrobox also allows you to enjoy cooling.

FTC6 Control System

The Ecodan® - Split systems are equipped with the new FTC6 control unit.

The backlit control, removable from the unit body and installable in a remote location, is equipped with a large display with graphic icons; from it, all the operating parameters can be adjusted in a simple and intuitive way, the functions are set (weekly timer, “holiday” mode, domestic water loading, etc.), diagnostics and consumption monitoring are accessed.

Thanks to the wireless control (optional) it is possible to remotely detect the room temperature and transmit it to the unit body, as well as modify the main operating parameters.

No fixing is required so it can be transported to different rooms.

Ecodan® R32 outdoor units

The new Ecodan® R32 SUZ-SWM outdoor units with capacities of 4.00, 6.00, 8.00 kW combined with the new D-Generation indoor units are the efficient and high-performance solution for heating, cooling and the production of domestic hot water.

- Low GWP R32 refrigerant ;

- Extended operating range down to -20°C ;

- Efficiency class A+++ in heating and A+ for the production of domestic hot water;

- Water flow temperature up to 60°C .

High performance in heating

The new Ecodan® R32 units are able to adapt to all system solutions and maintain high performance with external temperatures down to -20°C. Seasonal energy efficiency A+++ and SCOP up to 4.62 at low temperatures.

R32: a refrigerant with low environmental impact

The R32 refrigerant gas complies with European directives on the reduction of the greenhouse effect, having a lower GWP than R410A and not damaging the ozone layer.

- Exclusive AA Chassis

- The search for a product that prides itself on silent operation led to a complete redesign of the unit's chassis.

- The AA units are lower than the previous generation twin-fan units of the same power and have a discreet, sophisticated design.

To reduce fan noise, the new external AA chassis units use a larger diameter fan further away from the battery.

Extended operating range

Extended heating operating range down to -20°C. The new outdoor units are also suitable for the coldest climates. The new layout of the refrigerant circuit limits the risk of resonances and vibrations. The new compressor is installed on rubber supports and is efficiently acoustically insulated by a dedicated structure. The new fan design guarantees less acoustic impact. All these technological improvements guarantee a reduction of -10dB(A) in operating noise.

Small sizeThe new AA Chassis external units guarantee a smaller footprint thanks to their reduced height compared to the previous model.

High Performance

The new compressor of the AA outdoor units, more compact and powerful, allows to reach high SCOP values without sacrificing power. The entire series brilliantly exceeds the seasonal energy efficiency class A++ as defined by the European directive ErP Lotto 1

New base design

The base of the AA outdoor units has been redesigned to optimize and facilitate condensation drainage. The improvement of the defrost logic and the layout of the battery, combined with the new condensation drainage base, allow to avoid ice formation that could limit the comfort of use.

Inverter technology

Heat pumps typically reduce their heating capacity when the outside air temperature drops, just when the building's heat demand increases. Inverter technology can compensate for the lower heat output at low temperatures by increasing the compressor's rotation speed . Conversely, when the outside air temperature increases, the inverter modulates the frequency, adjusting the power supplied to the required heat demand and drastically reducing electricity consumption .

Product Warranty: All products for sale on our site are new and packaged. The warranty on this item is 24 months from the date of purchase.

Technical Data Sheet

Technical Data Sheet

- peso: 100.0 kg

- alimentazione: Single phase

- gas: R-32

- marca: MITSUBISHI ELECTRIC

- modello: ERSD-VM2D+SUZ-SWM40VA

- potenza in kw: 6

- tipologia : Air/Water