Air-Water Reversible Split Heat Pump Inverter Ferroli Omnia St 3.2 04 System With R-32 Electrical Integration With Control Included

Air-Water Reversible Split Heat Pump Inverter Ferroli Omnia St 3.2 04 System With R-32 Electrical Integration With Control Included is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

How shipping works

How shipping works

Shipping costs vary depending on the weight and shipping method of your order. Our shipping services:

- Standard Shipping: Estimated delivery within 2 to 5 business days

- Premium Shipping: Guaranteed delivery within 24 business hours

- Premium Shipping + Home Delivery: Guaranteed delivery within 24 business hours

See the tables for standard shipping prices for Italy and the Minor Islands and Disadvantaged Areas.

For more details on Premium Shipping, please visit the Premium Shipping page.

Customer service

Customer service

Our customer service team is dedicated to providing support to our customers with any issues or questions they may have before or after purchasing our products.

Use the direct communication channel to speak with one of our representatives, or send us an email at one of the addresses listed on the contact us page.

Our customer service team is made up of highly qualified professionals who are always ready to help customers resolve any issue or answer any question quickly and efficiently. We are committed to ensuring maximum customer satisfaction and providing the highest quality after-sales service. So, if you need assistance, don't hesitate to contact us; we'll be happy to help in any way we can.

Description

Description

- Model : OMNIA S 3.2 04

- Product Code : 0XHT4SWA

- Command included

Optional accessories

- CONNECT CRP remote control

Performance

- Useful power in heating with water set at 35° C: 4.20 kW

- Useful power in heating with water set at 45° C: 4.30 kW

- Useful power in heating with water set at 55° C: 4.40 kW

- Power absorbed with water set at 35°C: 0.82 kW

- Power absorbed with water set at 45°C: 1.70 kW

- Power absorbed with water set at 55°C: 1.49 kW

- Water flow rate with water set at 35°C: 722 l/h

- Water flow rate with water set at 45°C: 740 /h

- Water flow rate with water set at 55°C: 473 l/h

- Useful power in cooling with water set at 7 °C: 4.70 kW

- Useful power in cooling with water set at 18 °C: 4.50 kW

- Power absorbed with water set at 7°C: 1.36 kW

- Power absorbed with water set at 18°C: 0.82 kW

- Water flow rate with water set at 7°C: 808 l/h

- Water flow rate with water set at 18°C: 774 l/h

- Compressor type : Twin Rotary DC

- Number of compressors : 1

- Number of refrigeration circuits: 1

- Fan type : DC Axial

- Number of fans: 1

- Sound power level in heating : 53 ~ 60 dB(A)

- Sound power level in cooling : 52 ~ 60 dB(A)

- Liquid pipe diameter: 6.35 mm (1/4")

- Gas pipe diameter: 15.88 (5/8")

- Maximum pipe length: 30 m

- Maximum pipe height difference: 20 m

Technical data of the internal unit

- Exchanger type: Brazed stainless steel plates

- Expansion vessel volume: 10 litres

- Water safety valve calibration: 3 bar

- Minimum system water content: 40 litres

- System pipe diameter: 1" gas F

- Diameter of ACS pipes: 3/4" gas F

- Liquid pipe diameter: 9.52 mm (3/8")

- Gas pipe diameter: 15.88 (5/8")

Electrical Data

- Power supply (V,Hz,Ø) : 220~240/50/1

- Refrigerant gas: R32

Dimensions and Weight

- External unit dimensions (WxHxD): 1008x712x426 mm

- External unit weight: 58.0 Kg

- Internal unit dimensions (WxHxD): 595x1860x700 mm

5 years without worries

Efficiency meets comfort for integrated storage

OMNIA ST 3.2 is the evolution of OMNIA S 3.2 and is part of the new range of Full Inverter R32 split heat pumps by Ferroli. When we talk about “split” we mean that the refrigeration circuit is divided between the two units, the external one and the internal one. The external unit contains the heart of the refrigeration circuit, from the compressor to the fan with the air side exchanger, which is connected with the refrigerant gas pipes to the internal unit.

The internal unit contains the heart of the generator's hydraulic circuit with all the main pre-installed components, such as the high-efficiency circulator and the expansion vessel, to allow for safe, practical and fast installation. The OMNIA ST 3.2 differs from the OMNIA S 3.2 in having an accumulation tank for Domestic Hot Water integrated directly into the internal unit. This accumulation is 190L for sizes 4 to 10, while it is 240L for the larger ones, from 12 to 16T. But not only that, OMNIA ST 3.2 can be customized according to your needs, with an 18L inertial kit, a kit for solar integration on the accumulation or with a kit for the management of 2 different zones, classic direct and mixed, in case we need 2 different temperatures on the terminals in the house

Thanks to its wide operating range , among the widest on the market, OMNIA ST 3.2 works down to -25°C external and produces hot water up to 65°C in nominal conditions. The new Full Inverter concept by Ferroli uses DC inverter modulations on the 3 main energy-consuming components of the machine, i.e. compressor, fan and pump. This allows the power supplied to be modulated by finely tracking the thermal load and allowing the user very high efficiencies and significant energy savings . Furthermore, the Full Inverter concept by Ferroli allows the inrush currents to be reduced, avoiding surges in the network and guaranteeing a longer useful life for the components. With noise levels among the lowest on the market , OMNIA ST 3.2 is able to satisfy all system requirements, but can easily be integrated with a Ferroli boiler .

The internal unit, the heart of the hydraulic distribution

If the external unit contains the heart of the refrigeration circuit, the Internal Unit contains the heart of the hydraulic circuit. OMNIA ST 3.2 is much more than an exchanger with a pump. The hydronic module includes all the main components of the system and can be customized according to the user's needs. Stainless steel plate exchanger, pressure gauge and pressure sensors, expansion vessel, safety valve, automatic vent and brushless DC circulator are just some of the components you will find inside

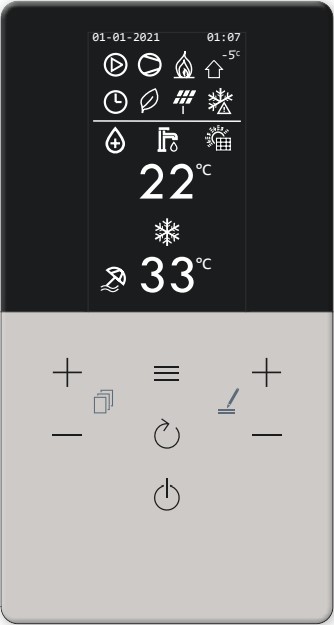

The control system

The User Interface has been equipped with Capsense technology with 2.8” graphic display, which allows the user to interact with the product in an easy and extremely simple way

Modbus protocol It can be interfaced with BMS/BACS automation and management systems

Heating and cooling Full Inverter modulation finely follows the desired setpoints, with the possibility of setting climatic curves in heating and cooling, further optimising the user's consumption

Domestic hot water production When the DHW Temperature probe calls the machine it automatically diverts to the domestic hot water boiler with a dedicated DHW Setpoint. 3-way diverter valve supplied as standard

Smart Grid Inputs from photovoltaic and grid Digital Smart Grid inputs for managing an input from a photovoltaic system and from the electricity grid. These allow you to optimise consumption and costs on your bill

Electric heating element for ACS boiler The ACS electric integration serves as an integration, anti-legionella or reserve source in the event of an anomaly

Fast ACS Priority to DHW production to bring the boiler to the setpoint in the shortest possible time

Anti-legionella function Allows you to set weekly anti-legionella cycles

Silent mode Reduces the compressor frequency and fan speed, thus significantly reducing noise. Programmable on time slots

ON/OFF From external contact. Activation and deactivation via an external contact, for example from a zone thermostat

Hot / cold From external contacts. Summer/winter switching signal from outside, e.g. from the zone thermostat

ECO function Dedicated setpoint for “ Eco ” operation. Can be set with daily time slot

Antifreeze protection Heat pump operation in heating mode with circulator ON and possible electric booster

The brand new Connect CRP and Connect CRP Zone

The on-board interface communicates easily with the new intelligent Connect CRP systems, which can manage up to 8 thermostats divided into 2 zones, one direct and one mixed .

Connect CRP is the brand new remote controller accessible via APP , available for both iOS and Android .

The Connect CRP Zone is a zone thermostat that communicates via RF with the Connect CRP. It can be inserted into a classic 502 box, or left stand-alone on its practical table feet.

Product Warranty: All products for sale on our site are new and packaged. The warranty on this item is 24 months from the date of purchase.

Technical Data Sheet

Technical Data Sheet

- peso: 50.0 kg

- alimentazione: Single phase

- classe efficienza energetica: A

- gas: R-32

- marca: Ferroli

- modello: OMNIA_ST_04_1

- potenza in kw: 4

- tipologia : Splitted