Mini Chiller Daikin Inverter Heat Pump Air Water Ewya-011dw1p From 11 Kw Three-Phase R-32 Class A +++

Mini Chiller Daikin Inverter Heat Pump Air Water Ewya-011dw1p From 11 Kw Three-Phase R-32 Class A +++ is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

How shipping works

How shipping works

Shipping costs vary depending on the weight and shipping method of your order. Our shipping services:

- Standard Shipping: Estimated delivery within 2 to 5 business days

- Premium Shipping: Guaranteed delivery within 24 business hours

- Premium Shipping + Home Delivery: Guaranteed delivery within 24 business hours

See the tables for standard shipping prices for Italy and the Minor Islands and Disadvantaged Areas.

For more details on Premium Shipping, please visit the Premium Shipping page.

Customer service

Customer service

Our customer service team is dedicated to providing support to our customers with any issues or questions they may have before or after purchasing our products.

Use the direct communication channel to speak with one of our representatives, or send us an email at one of the addresses listed on the contact us page.

Our customer service team is made up of highly qualified professionals who are always ready to help customers resolve any issue or answer any question quickly and efficiently. We are committed to ensuring maximum customer satisfaction and providing the highest quality after-sales service. So, if you need assistance, don't hesitate to contact us; we'll be happy to help in any way we can.

Description

Description

OPTIONAL FIRST START-UP, CONTACT YOUR LOCAL SERVICE CENTER!

Technical Features

- Model : EWYA011D1WP

- Power: 11.0 kW

Energy Efficiency

- SEER : 5.79

- SCOP : 4.73

- Energy Efficiency Class in Heating: A+++

- Cooling capacity: 11.6 kW

- Heating capacity: 10.6 kW

- Cooling Power Consumption: 3.56 kW

- Heating absorption: 2.18 kW

- Air Flow Rate : 55.8 ~ 70 m 3 /min

- Water flow rate: 30.3 l/min

- Sound Power Level: 67 dB(A)

- Sound pressure level: 47.7 dB(A)

Electrical Data

- Power supply (V,Hz,Ø) : 380~415/50/3

- Refrigerant gas: R32

- Cooling: -10° ~ 43° C

- Heating: -25° ~ 25° C

- Cooling: -5° ~ 22° C

- Heating: 9° ~ 60° C

- Hydraulic Pipe Diameter: 25.4 mm (1") Male

- Pipe connection diameter: 25.4 mm (1")

Dimensions and Weight

- Dimensions (HxWxD): 1053x1500x650 mm

- Internal Unit Weight: 164 Kg

Daikin Mini Chiller Systems Small chilled or heated water production systems

Why the inverter?

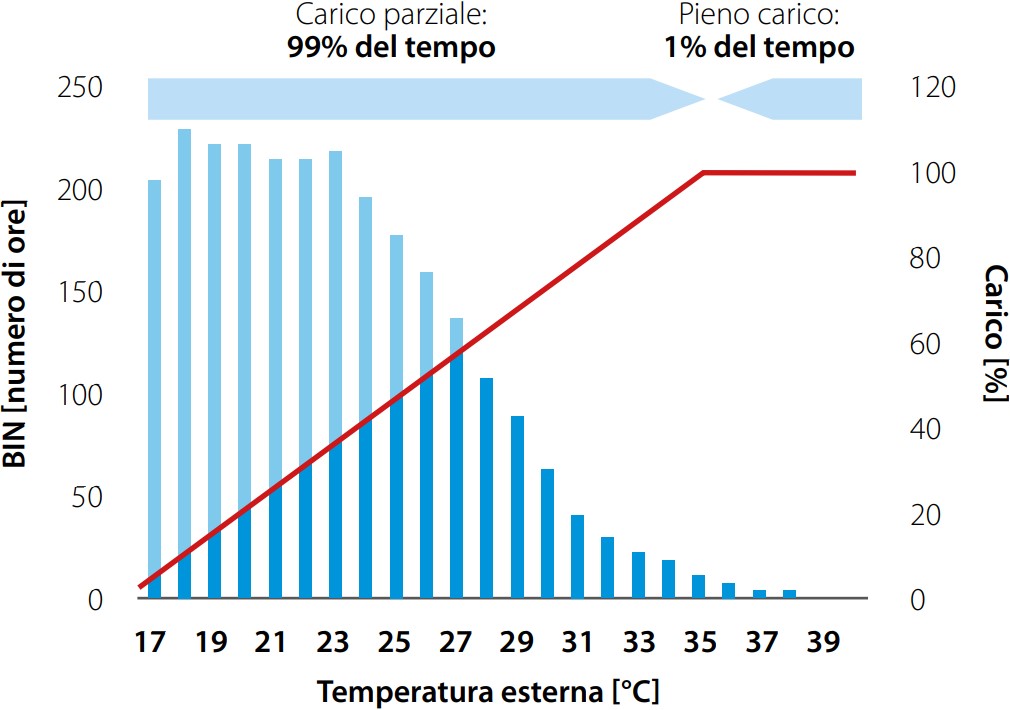

The Inverter allows the compressor power to be continuously modulated based on thermal load requirements by varying its rpm. This principle, compared to traditional technology that divides the power into discrete steps of even high capacity, guarantees the end customer energy savings and better control of the system's operating parameters. Most of the time, a building's cooling requirement is less than the system's maximum load capacity. The greater the variations in annual load, the more vital it is to ensure that the units operate efficiently.

Energy Saving Absorption proportional to the power supplied

The Inverter offers, for the chiller as a whole, the possibility of significantly increasing its efficiency at partial loads, that is, the condition in which, seasonally, the chiller will work for most of the time, guaranteeing the best performance and reaching high values of average summer seasonal efficiency ( ESEER ).

Furthermore, with the introduction of the European SCOP (seasonal COP ) indicator, the adoption of modulating systems and inverter technology allows for the optimisation of consumption even in winter, in line with the best requirements requested by the new energy index.

What is SEER?

«Seasonal Energy Efficiency Ratio» ( SEER ): the seasonal energy efficiency ratio of the unit representative of the entire cooling season, calculated as the reference annual cooling demand divided by the annual electricity consumption for cooling purposes.

New parameter representing the seasonal efficiency of the product . The SEER value is calculated over a period of 2600 hours of operation during the year. Of these, only 30 hours of operation at full load are recorded.

Ideal Temperature Continuous power and noise regulation

The ability to work in modulation offers the guarantee of accurate control of the fluid temperature, regulated at a fixed point on the delivery to the system. This feature is ideal for industrial applications and precision temperature control, as it excludes constant compressor stops/starts, responsible for electrical and mechanical wear. A further advantage is the lower acoustic impact when compressors and fans operate partially, or in conditions of lower power output demand, while ensuring greater stability for the water temperature.

Lower System Costs Reduction of system water accumulation/content (-60%)

Thanks to the ability to react quickly to load variations, chillers that use Inverter technology can work correctly with a strong reduction in water content in the system (-60% compared to traditional chillers). This allows for a reduction in thermal inertia, with energy optimization and shorter start-up times. The result is a significant saving in system costs as the accumulation tank is no longer necessary.

Electrical advantages

From an electrical point of view, the Inverter introduces two great advantages:

Low inrush currents, significantly lower than the nominal operating current, which results in a lower cost for the electrical components to be installed

More power available when needed

The Inverter allows you to vary the power supplied; by powering the compressor at a higher frequency it is possible to reach maximum power values higher than the nominal ones. This offers benefits in the system's start-up but, above all, it becomes an evident technical plus when the machine works in extreme operating ranges. For example, traditional air-cooled heat pumps are usually combined with boilers to compensate for the efficiency deficit due to rigid external temperatures. Inverter heat pumps can benefit from greater power when the ambient conditions require it, losing only 15% of performance in the transition from 7°C to -10°C of external air (in the case of an ON-OFF the reduction would be ~40%), guaranteeing a water temperature of 50°C at all regimes. These advanced heat pumps can therefore be considered "primary", since they allow you to avoid the use of boilers.

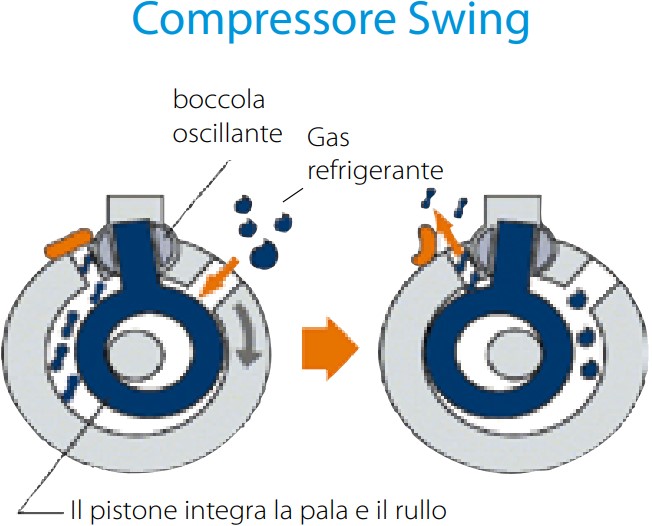

Compressors developed and produced by Daikin

Daikin has always been at the forefront of the development of compression technology and now offers a complete range of Swing, Scroll, Screw and Centrifugal compressors. As a result, Inverter compressor control is applied to our entire product range, offering greater comfort and ensuring a more efficient system.

Scroll compressor for capacity control

Daikin Scroll compressors are compact and suitable for use with R32 refrigerant, ensuring constant reliability and high efficiency throughout their entire life cycle. Optimized for use in small and medium-sized systems, Scroll compressors are combined with air-cooled and water-cooled chillers.

Characteristics:

› Simple, compact and robust

› No valves or oscillating joint mechanisms, to ensure maximum reliability

› Constant compression, to ensure low energy consumption

› Greater compression efficiency thanks to the absence of volumetric re-expansion

› Low noise

› Low inrush current

Advantages:

› Choosing a product in R32 reduces the environmental impact by 68% compared to R410A and directly leads to lower energy consumption thanks to its high energy efficiency.

› Inverter Chillers

› Hermetically sealed inverter compressor

› New outdoor unit coating

› Separate MMI-2 controller for internal installation

Product Warranty: All products for sale on our site are new and packaged. The warranty on this item is 24 months from the date of purchase.

Technical Data Sheet

Technical Data Sheet

- peso: 120.0 kg

- alimentazione: Three-phase

- gas: R-32

- marca: Daikin

- modello: EWYA-011DW1P

- potenza in kw: 11

- tipologia : Air/Water