Gas Boiler Beretta Mynute Green E 25 Csi Methane Condensing Complete With Fume Exhaust Kit -New Erp

Gas Boiler Beretta Mynute Green E 25 Csi Methane Condensing Complete With Fume Exhaust Kit -New Erp - Coaxial smoke kit is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

How shipping works

How shipping works

Shipping costs vary depending on the weight and shipping method of your order. Our shipping services:

- Standard Shipping: Estimated delivery within 2 to 5 business days

- Premium Shipping: Guaranteed delivery within 24 business hours

- Premium Shipping + Home Delivery: Guaranteed delivery within 24 business hours

See the tables for standard shipping prices for Italy and the Minor Islands and Disadvantaged Areas.

For more details on Premium Shipping, please visit the Premium Shipping page.

Customer service

Customer service

Our customer service team is dedicated to providing support to our customers with any issues or questions they may have before or after purchasing our products.

Use the direct communication channel to speak with one of our representatives, or send us an email at one of the addresses listed on the contact us page.

Our customer service team is made up of highly qualified professionals who are always ready to help customers resolve any issue or answer any question quickly and efficiently. We are committed to ensuring maximum customer satisfaction and providing the highest quality after-sales service. So, if you need assistance, don't hesitate to contact us; we'll be happy to help in any way we can.

Description

Description

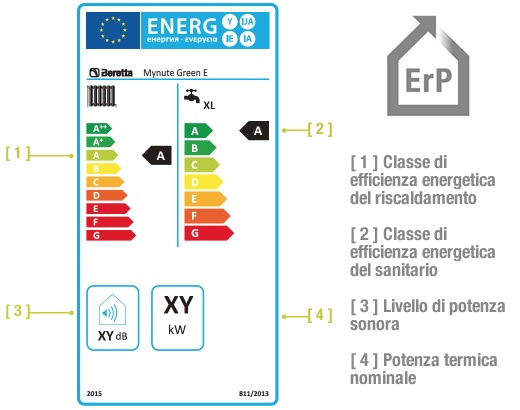

Mynute Green E - ErP

The entry into force of the European Directive ErP (26.09.2015) provides that even generators for the production of heating and domestic hot water are classified through the appropriate energy label indicating the class. Compulsory labeling provides greater transparency on the characteristics of the products which can be easily compared, helping the user to find those with greater efficiency. Consequently, even with boilers it will be easier to contribute to the achievement of the "20-20-20" objective set for the year 2020 which consists of: reducing greenhouse gas emissions (CO2 ) by 20%, increasing by 20 % use of renewable energies and reduce energy consumption by 20% in EU countries. The new Beretta condenser exchanger with front access The Mynute Green E boiler is equipped with the new Beretta condensing exchanger with front access. An innovative system of guides allows it to move like a drawer, making disassembly for cleaning required by current regulations much faster. Continuous research has allowed Beretta to obtain an exchanger characterized by a considerable increase in performance: 94% average seasonal efficiency calculated according to the European ErP Directive. The exchanger comes from a single aluminum tube, without welding thanks to an innovative production process. The high thermal conductivity of aluminium, much higher than that of steel, allows for greater uniformity in temperature distribution. The single pipe architecture (series circuit) allows for a large section for the passage of water with the advantage of reducing pressure drops and preventing the deposit of impurities, keeping the exchanger performing over time. With the new Beretta condensing exchanger, boiler performance improves up to an average seasonal efficiency of 94%. Mynute Green E, the elegant The new Mynute Green E is characterized by a particularly elegant aesthetic and is equipped with a simple and intuitive digital display which makes information on the status of the appliance immediately usable. The modern ergonomic knobs allow you to easily select all the functions necessary for using and setting the boiler. Flex modulating circulators: optimized performance, low consumption Mynute Green E uses a synchronous modulating circulator with low energy consumption, as required by the European ErP Directive. Thanks to this new technology, the electric motor of the circulator offers an Energy Effi ciency Index of less than 0.20, which means significantly reduced electricity consumption. The new circulator works proportionally to the power supplied by the boiler, thus contributing to a further reduction in electricity consumption. In case of need on the heating system, it is possible to change the head without having to replace the standard circulator with a high head one, the name “Flex” derives from this feature. Up to 49 meters of ducting With Mynute Green E it is possible to comfortably intubate even the most "difficult" flues thanks to the approval for flue Ø 50mm. The main 50mm flue ducts are available in the Beretta price list catalogue, while the boiler manuals provide indications of the maximum length, which differ according to the boiler power. Characteristics:

|

||

Beretta is “ERP”. The concrete commitment towards an eco-sustainable future

The acronym ErP, acronym of "Energy related Products" (Products connected to the use of energy), identifies the Directive 2009/125/EC aimed at reducing the energy consumption of products through eco-compatible design. Starting from 26 September 2015 , the date of its effective entry into force in the European Union, it will mark an epochal turning point for heating products and the production of domestic hot water. On that date, other regulations issued at the same time for the energy labeling of products to supplement the corresponding Directive 2010/30/EU will also become effective. The regulation provides that all products intended for heating and for the production of domestic hot water with a nominal thermal power lower than or equal to 70 kW can only be placed on the market with an energy label that highlights the efficiency class * . Different energy efficiency labels have been provided based on the different types of appliances/technologies, but all have the same graduated color scale that identifies the various levels of efficiency at a glance. The purpose of the labels is to give the consumer the possibility to easily identify the level of efficiency of a product and to be able to make a homogeneous comparison between products that use different technologies. For products whose transformation efficiency is influenced by external conditions, such as heat pumps, the efficiency data is reported by climatic bands. In addition to the product labels, the European regulation has provided for the creation of a system label in case systems are created with different appliances, components and related controls. This second type of labeling, thanks to the virtuous synergy between the different elements, will make it possible to create systems capable of reaching levels of efficiency even higher than those of the individual devices. Also starting from the same date, new seasonal efficiency limits will be triggered for products intended for heating and combined. These for products with nominal thermal power equal to or less than 400kW, will prevent less efficient products from being placed on the market. The obligation to comply with minimum heat loss limits will also apply to DHW tanks. For primary water tanks, these will be subject to compliance with an energy classification based on heat dispersion. For sanitary accumulations, up to 500 liters there will be a labeling obligation, from 500 to 2000 liters will be bound to compliance with the energy classification. For heat pumps for heating and mixed appliances, in addition to the seasonal efficiency limits, there will be specific noise emission limits for power sizes. Even water heaters, whether gas, heat pump or solar, in order to be placed on the market, in addition to energy labelling, will have to comply with a series of requirements in terms of efficiency.

|

Warranty

All products for sale on our site are new and packed. The guarantee on this item is 24 months from the date of purchase.

Technical Data Sheet

Technical Data Sheet

- peso: 35.0 kg

- classe energetica produzione acs: A

- classe energetica riscaldamento: A

- gas: Methane

- marca: Beretta

- metri quadri : 150

- modello: CALD_301

- potenza in kw: 25

- potenza nominale: 25

- superficie riscaldabile mq: 150