Technical Features

- Dimensions External Diameter: 16 mm

- Thickness: 1mm

- Roll Length: 50m

- Minimum Coating Thickness: 10 mm

- Burst Pressure : 28.05MPa

- Working Pressure : 7.01MPa

- Water content: 0.154 l/m

SMISOL® Frio Fears neither the Heat nor the Cold

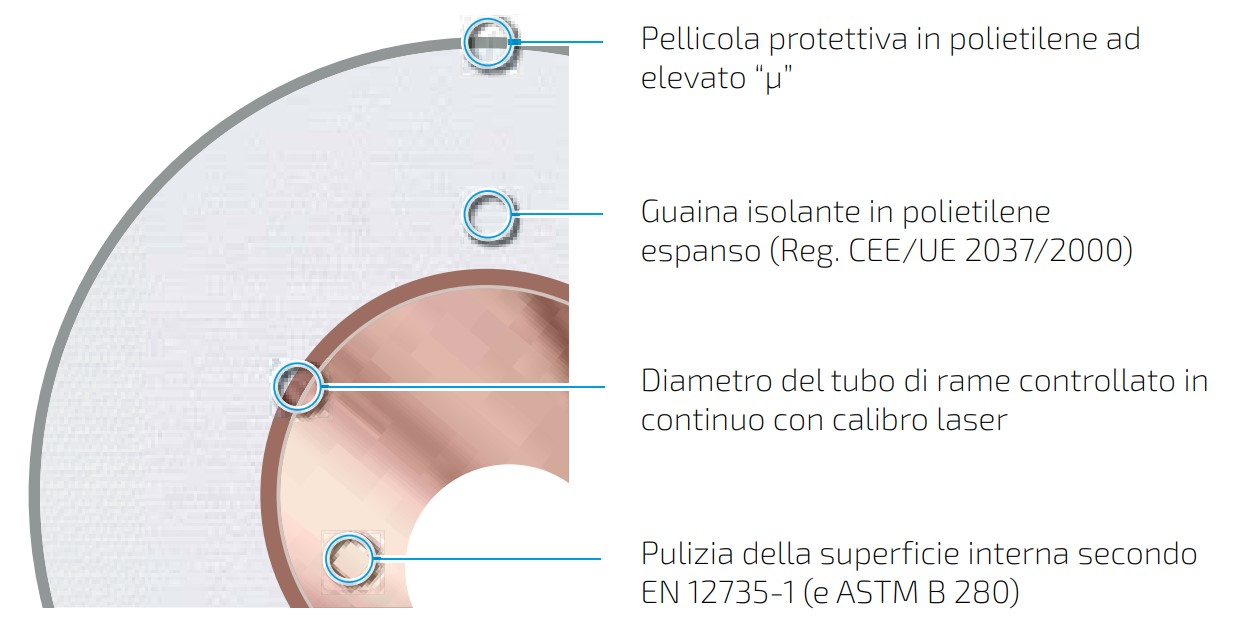

It is the copper tube produced according to the EN 12735-1 standard (and ASTM B 68/M), and is pre-insulated in closed-cell expanded polyethylene of regular and uniformly distributed dimensions (UNI EN 14114). It is distributed in rolls, having the dimensions of the diameter of the tube in millimetres. The insulating sheath is produced in full compliance with the European Regulation EEC/EU 2037/2000 which requires the use of expanded insulating sheaths without the use of CFCs and HCFCs, gases harmful to health and the environment. The thickness of the sheath is also sized in such a way as to satisfy the multiple needs of this application sector. In consideration of the particular specificity of the field of use, special attention is paid to the external protective polyethylene film aimed at preventing the formation of condensation on the external wall of the product.

Internal Surface

The internal surface of the copper tube is shiny, clean and dry , fundamental characteristics of a product normally available on the market for industrial use. This peculiarity allows to obtain an integrated system with the terminal elements of the plant. The particular internal cleanliness of SMISOL® Frio is safeguarded by closing the ends of each roll with caps, directly during the production phase.

External Protection

Closed-cell expanded polyethylene coating with an average value of the water vapour diffusion resistance factor “µ” greater than 15000. The insulating sheath is produced in full compliance with the European Regulation EEC/EU 2037/2000 which requires the use of expanded insulating sheaths without the use of CFCs and HCFCs, gases harmful to health and the environment and has a fire behaviour of class BL-s1-d0 according to EN 13501-1.

Coating Features

- Thermal conductivity: λ ≤0.040 W/m°C.

- Average value of the water vapour diffusion resistance factor “µ” greater than 15000.

- Average coating density: 33 kg/m3.

- Free from ammonia residues.

- Excellent resistance to external chemical agents.

- Non-flammable class BL-s1-d0 according to EN 13501-1

- Free from CFCs and HCFCs (Reg. EEC/EU 2037/2000)

Design Guidelines

To avoid possible condensation phenomena on the pipe, it is necessary to check the environmental conditions in which the product is installed: relative humidity of the environment, temperature of the environment and of the fluid inside the pipe. In this regard, it is recommended to check using the Psychrometric chart

Fields of Use

- Refrigeration.

- Transport of heat transfer fluids for multifunctional systems

Product Warranty: All products for sale on our site are new and packaged. The warranty on this item is 24 months from the date of purchase.